- Hyperion Robotics was founded in Espoo in 2018.

- Their aim is to provide faster, safer and environmentally friendly construction via 3D printing.

- Hyperion Robotics provides its clients with printing robots on a rental basis.

- The company’s founders mix construction and 3D printing experiences.

- The startup was a finalist of the 100 Wolves Pitching Contest.

Do you want a house? Be prepared that it will take a lot of time before it is built. The construction firm will have to allocate much manpower and spend weeks if not months on the site, and you’ll need to find a way to get rid of all the waste. People make use of the skip bins for hire sydney has for a reason, after all. Your desire for a home will also leave a significant carbon print. Not a good step in the let’s-cut-the-greenhouse-gases era. But what if there is a better way?

Enter Hyperion Robotics. A Finnish startup from Espoo is about to disrupt the conservative construction industry that has resisted progress for way too long. What is the magic? Like in many other areas, 3D printing is bringing enlightenment. Not only does it make construction faster, but it is also much more environmentally friendly. As Hyperion Robotics s CEO Fernando De los Rios explains:

„Our 3D printing process is faster, safer and sustainable compared to traditional building of concrete elements.”

Jan Cermak, Head of R&D at the Czech company ERC-TECH, agrees that concrete printing can save material, time and human resources and adds: “However there could be a problem of nonexistent legislation. We also lack testing methods for this type of construction.” says Cermak, whose company deals with environmental burdens of construction and demolition waste disposal.

The construction industry in central Europe still reels from the pandemic. Eurostat s data for May 2020 (the latest available) show the situation is most difficult in Hungary (20,1 percent decline in comparison with May 2019). Poland and Czechia fare better though still in decline too (-3.0 and -7.6).

Let robots do the hard work

Construction usually requires a certain amount of workforce. While there are a few firms that tend to make use of growing technologies like construction digital forms, for instance, to expedite the processes faster, work personnel still is a criterion that they require the most for this business. Thus, a one-hundred square-meter house needs from six to eight workers locked for several weeks. Not anymore. Hyperion Robotics can provide a robot responsible for all the heavy lifting. Specifically, while a robot prints the entire structure, the rest of house components such as mechanical, electrical, and plumbing systems can be installed with companies able to get specific equipment (such as the kind seen if you check out Platforms and Ladders) to get these components into place.

And that also has a significant impact on people’s safety. Workers are no longer exposed to all the potentially dangerous situations that can occur on the building site. The robots are taking over.

Disposing of molds makes you green

But the greatest advantage is the friendliness to the environment. The construction sector indulges itself in a lot of waste. Molds are the main culprit since “(they) are typically used a few times and they end up as waste, increasing the carbon footprint of the construction process”, Mr. De los Rios says. The 3D printing deals with it as there is no need to create them at all. Disposing of molds also reduces the costs. Hyperion Robotics states their solution can reduce the use of concrete by half.

This brings us to the main point. In this case, ecology also refers to monetary value. By reducing time and waste, construction companies (such as Knockdown rebuild Sydney) can save a significant amount of money. These cost savings can then be passed on to the company’s customers. As a result, more people may be able to afford to build their dream homes. You can also have your home designed exactly how you want it without any complications.

Who are they?

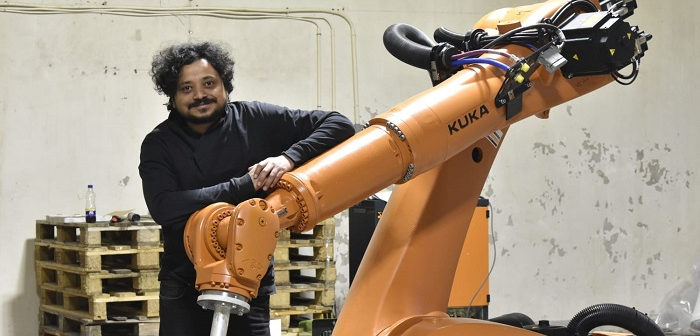

Hyperion Robotics draws its strengths from their co-founders backgrounds. In 2018, Mr. De los Rios joined forces with Ashish Mohite – Hyperion Robotics s Chief Design Officer. Whereas Mr. De los Rios comes from the construction industry, Mr. Mohite was a PhD researcher at Aalto University in Finland with more than 8 years of experience in 3D printing. Together they crafted a solution that can significantly reduce the global CO2 emissions. Not only that. They have already attended the 100 WOLVES PITCHING CONTEST too.

The business model works like this. Hyperion Robotics provides its clients with 3D printing robots on a rental basis. The company also assists them to ensure a smooth development of their projects. That scope of usability is pretty wide – from nimble products like city benches to entire buildings. “We really root for Hyperion Robotics,” says architect Tomas Rousek, CEO at the Prague-based architecture company A-ETC. He collaborated with Hyperion Robotics on building family houses in Czechia. “I am glad that this technology is able to ensure new forms and construction quickly,” Mr. Rousek adds.

So what about the future? Given the need of mitigating climate change, Hyperion Robotics s position is very well placed. The company says concrete usage reduced by half can achieve an eight percent reduction of CO2 emissions. Not a negligible figure indeed.