- Lithuanian startup Sort A Brick secures EUR 1.5M from FIRSTPICK and NGL to reuse pre-loved LEGOs

- The team developed advanced AI computer vision and machinery to sort 10,000+ unique LEGO parts

- The company overcomes market skepticism and plans global expansion for sustainable play

This May, Sort A Brick—Lithuania’s most unusual startup that sorts and reuses pre-loved LEGO bricks—announced its Pre-Seed round of EUR 1.5M. The investment came from the well-known Lithuanian VC fund/accelerator and the startup’s repeated supporter FIRSTPICK (invested in Micapass, among others), joined by NGL.

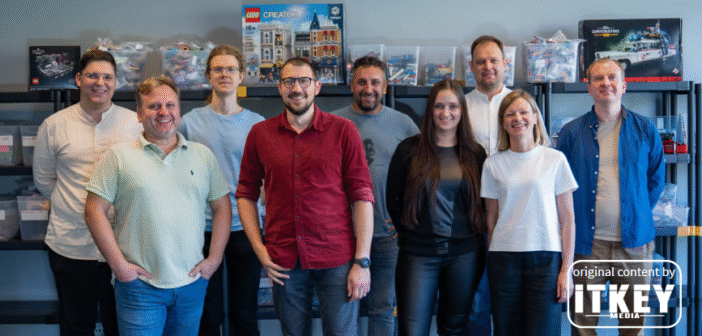

The Genesis of a Green Idea and a Green Dream Team

Ilya Malkin, Co-Founder at Sort A Brick

Sort A Brick’s co-founder Ilya Malkin ran a management consulting business for 15+ years, which he sold in a management buyout. In 2019, with his classmates from Harvard Business School he also started a micro-VC fund to invest in high-growth startups in the USA.

The spark for Sort A Brick came from Mr Malkin’s home: watching his kids build LEGO sets once and then clamoring for a new one, he was joking about ending up bankrupt at this rate. Every startup entrepreneur’s joke is only partially a joke, so he wondered if there was a smarter way to deal with used LEGOs.

It’s necessary to add that most LEGO parts are still made of ABS (acrylonitrile butadiene styrene) plastic, despite LEGO’s declared commitment to replace it with more sustainable materials by 2032. ABS is an incredibly durable material, practically indestructible. The use of this material is one of the big reasons why the toy industry is deemed a major culprit for the excessive use of plastic and the consequent environmental problems.

Seeing heaps of barely-used bricks gathering dust and knowing these plastic pieces virtually never die, Mr Malkin felt uniquely positioned to solve the problem as he understood both the pain and expense firsthand and had necessary entrepreneurial experience.

Aurimas Slapšys joined later and brought the technical know-how. Mr Slapšys’ expertise in both marketplace growth and tech innovation comes from over 8 years he spent at Vinted, Lithuania’s first unicorn, and leading product at an AI graphics startup.

The Path to Cracking the Code of Brick Sorting and Winning Over Skeptical Investors

After the launch of Sort A Brick in 2023, the company developed prototypes of brick recognition and sorting technology, including computer vision networks, machinery and software, and kicked off a pilot service in Germany in late 2024.

According to Mr Malkin, building the tech was the main hurdle. The computer vision networks had to recognize 10,000+ unique brick shapes in 100+ colors and tens of thousands of different decors, with near-perfect accuracy. In addition, it’s necessary to separate, transport, and sort bricks of varied size, weight and shape through the processing line without losing or misplacing them with a speed as high as a couple of parts per second.

‘Another major challenge was convincing investors that sorting old toy bricks can be a scalable business. In fact, Sifted jokingly dubbed Sort A Brick Europe’s weirdest VC deal of the year – beating even a pet funeral startup and a mushroom coffin maker. We took that in stride as a compliment for doing something bold and unconventional,’ Mr Malkin recalls.

Speaking of convinced investors, the founders share that they had no idea LEGO was so popular among the startup/VC crowd.

‘If it is, then maybe it’s a physical prototyping in its purest form. It’s nostalgic, creative, and hands-on. Founders love to build – whether it’s companies or brick castles. Plus, it’s way more satisfying than debugging code,’ Mr Malkin comments.

Mantas Mikuckas, Angel Investor, Co-Founder at Vinted

For example, here’s what Mantas Mikuckas, Vinted’s co-founder and Sort A Brick’s earliest supporter, has to say:

‘Circular businesses have huge potential because they address real problems while also cutting CO2 emissions. Sort A Brick is a great example, letting kids enjoy their toys more while saving parents money and reducing their environmental footprint. It has also developed a truly unique approach, as the only company that actually sorts LEGO bricks for you.’

Sort A Brick’s Set of Secret Sauces

Essentially, Sort A Brick collects boxes of mixed bricks from customers, cleans them, photographs each from all sides, and runs AI to identify every unique part. Then the digital inventory gets matched against LEGO’s entire set catalog, rebuildable models are found, missing pieces are filled, all bricks are sorted into separate bags, and sent out as ready-to-build sets.

‘Sort A Brick’s edge comes from a combination of homegrown technology and hard-earned know-how that is tough to duplicate,’ Mr Malkin states.

At its heart is a proprietary computer vision system that recognizes an astonishing variety of LEGO parts. It is apparently complicated to train models to distinguish over 10,000 shapes and 100+ colors with near 100% accuracy. The team invested heavily in optimal imaging setup and neural network training for computer vision to identify the tiniest differences between bricks.

‘This is not perfect yet, but we can already accurately identify all of the most popular shapes and are working on improving color recognition as we speak,’ Mr Slapšys assures.

Custom mechanical systems are also in place – conveyor feeds, camera chambers, sorting bins, and more. It’s integrated machinery that physically separates parts into the right groups with the help of proprietary software recognizing these parts.

‘Another big competitive moat is the upfront cost and time we’ve sunk into R&D and process development. Our business model, while hugely promising, isn’t easy to copy – the barrier to entry is high. You need to develop complex hardware, invest in AI training on a very specialized dataset, and accumulate tons of LEGO-specific knowledge. It’s not like a pure software startup that can scale overnight – in our case, scaling means building physical sorting hubs and refining algorithms that deal with thousands of tiny variables,’ Mr Slapšys tells ITKeyMedia.

Navigating LEGO Brand Landscape

Aurimas Slapšys, Co-Founder and Head of Software and Data at Sort A Brick

Working with a brand like LEGO apparently involves navigating potential legal challenges as well. In this regard, Sort A Brick adheres to LEGO’s Fair Play policy and other regulations with respect to LEGO’s intellectual property.

Reportedly, LEGO has invested significantly in sustainability, but their core business of selling new sets creates a conflict of interest with promoting reuse. It is known that they’ve tested small-scale buy-back and recycling programs in a few select countries and acquired BrickLink, a second-hand marketplace for LEGO sets, but its widespread development remains limited. One can only guess that it may be connected to the possible risk of cannibalizing LEGO’s primary sales. Regardless, this underscores a gap in large-scale reuse solutions for LEGO bricks.

Future Visions Beyond Bricks

As for Sort A Brick, reuse is just the start. The company’s plans include local hubs to cut shipping emissions, offer bulk pickups, and use recycled packaging. Carbon offsetting and EV logistics are further down the road.

‘We aim for joy with a low footprint – planet-friendly play, not just pretty packaging,’ Mr Malkin states.

For now, the new investment allows Sort A Brick to scale automation, further improve accuracy and throughput, and ramp up its services in Germany: More sets, faster sorting, lower cost. According to the founders, the next round of investment is likely to exceed EUR 2.5M, to happen as soon as this autumn, and to bring the startup closer to the founders’ bigger dream–a global network of micro sorting centers.

Potentially, Sort A Brick’s system could eventually sort other toys, puzzle pieces, or even small hardware,—any small parts that need to be ID’d and sorted precisely.

‘We insist that we’re not just a service company, we’re deep tech. While the idea of ‘giving old bricks new life’ might sound simple, doing it at scale the way we do is anything but simple – that’s our secret sauce that sets us apart from any potential competition. All of it is not final, of course. We will continue building and improving all of the core technical elements for the upcoming future to make brick sorting as fast and as reliable to support viable high-growth business,’ Mr Malkin concludes.

Sort A Brick’s approach to reusing pre-loved LEGO bricks is crucial for environmental sustainability, tackling the widespread issue of plastic waste from the toy industry. But beyond its immediate impact on reducing waste, the company’s pioneering advanced sorting technology showcases how sophisticated AI and hardware can precisely identify and categorize intricate objects at scale. This dual focus positions Sort A Brick as a leader in both circular economy initiatives and deep tech innovation, with potential applications far beyond toy bricks.

Kostiantyn is a freelance writer from Crimea but based in Lviv. He loves writing about IT and high tech because those topics are always upbeat and he’s an inherent optimist!